Each stage of our remanufacturing process is designed to be safe and efficient, to ensure each component is built to the highest quality standard at the lowest possible cost, resulting in maximum customer value. OEM Remanufacturing's quality management system and focus on Lean manufacturing reflects our commitment to providing exceptional value, enhancing the customer experience, and to continually improving OEM Remanufacturing's products and service capabilities.

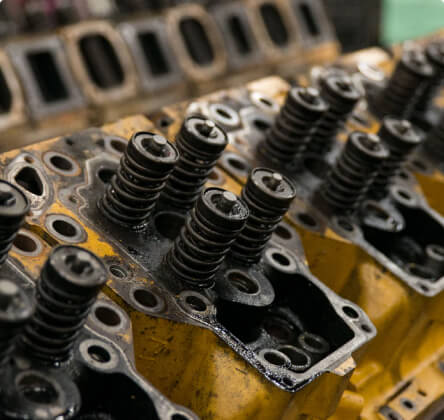

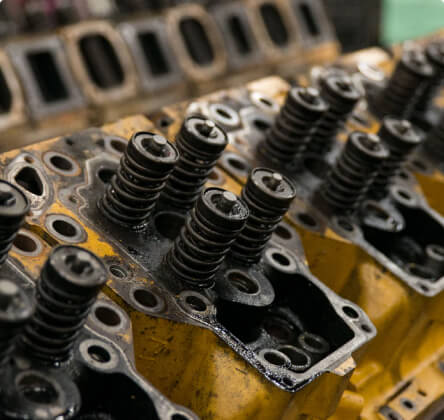

Used components are carefully inspected and disassembled with care. All components that flow through the OEM Reman’s lean processes are rebuilt to a standard bill of materials, incorporating any technical changes required including service letter information to ensure all components remanufactured at OEM contain the latest updates for parts and/or salvage operations.

Once the parts are ready for inspection, we’ll determine if any can be reused, salvaged or replaced with new. We use the necessary measuring devices to make sure they meet all manufacturer's reusability guidelines as part of OEM’s extensive quality assurance program.

We continually invest in new technology for our 70,000 square foot machine shop so all machining work for the remanufacture of a component is as sustainable as possible. It means we salvage what we can after disassembly to build like new while meeting guidelines – Our remanufactured parts can sometimes be better than new as we’ve used new technology in the build process that may not have originally been there for the original part.

All components are assembled by product specific technicians who are organized into specialized employee teams. The allows the technicians to focus on specific processes. OEM has developed a pool of talented experts who consistently product top quality components.

The right training and the right equipment goes a long way to cementing the relationship with our customers – as part of the engine and powertrain testing process, technicians run all engines at full horsepower to reflect actual, rather than simulated, operating conditions. All benches are computer-controlled so technicians are unable to intervene and provide manual passes.

Once a component is remanufactured and tested (if necessary), it has one last stop at OEM before it arrives with the customer. We send it to be painted, packaged, signed off and shipped. We put as much expertise and care into protecting your parts as we do – multiple layers of protective material during packaging prevent scratching or dents of parts throughout the entire delivery process.